Sgriw Pen Cap Soced Hecsagon ASME B18.3 ASTM A574 F837

Sgriw Pen Cap Soced Hecsagon ASME B18.3 ASTM A574 F837

Disgrifiad

CYFLYMYmateb

CYFLYMDyfynbris

CYFLYMDosbarthu

PAROD I'W LLONGIO DOSBARTHU

10000+ SKU yn y warws

Rydym yn Ymrwymo ar gyfer eitemau RTS:

70% eitemau a ddanfonwyd o fewn 5 diwrnod

80% eitemau a ddanfonwyd o fewn 7 diwrnod

90% eitemau a ddanfonwydo fewn 10 diwrnod

Archebion swmp, cysylltwch â gwasanaeth cwsmeriaid

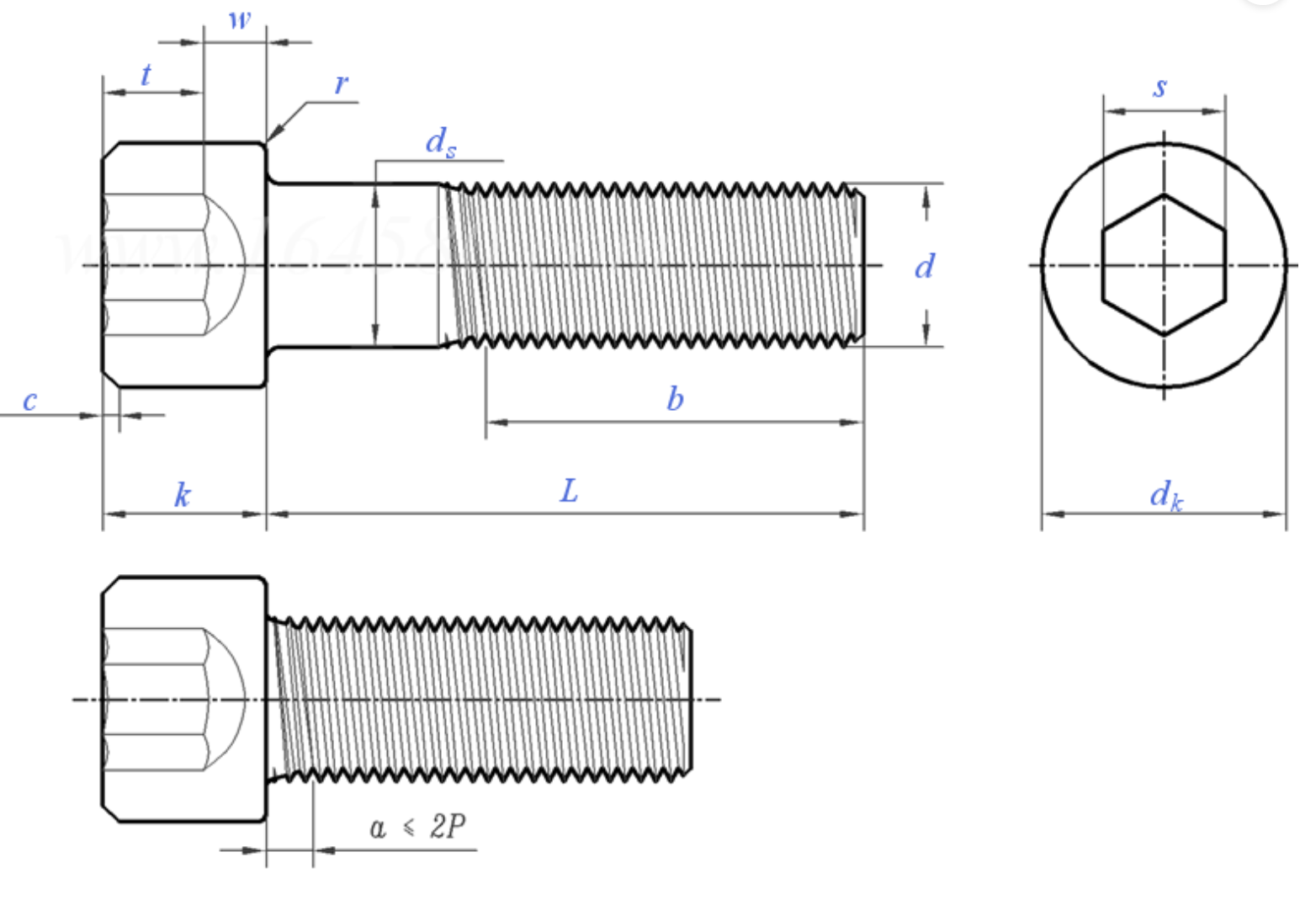

| Maint | 0# | 1# | 2# | 3# | 4# | 5# | 6# | 8# | 10# | 12# | 1/4 | 5/16 | ||

| d | Diamedr yr Edau | 0.06 | 0.073 | 0.086 | 0.099 | 0.112 | 0.125 | 0.138 | 0.164 | 0.19 | 0.216 | 0.25 | 0.3125 | |

| PP | UNC | - | 64 | 56 | 48 | 40 | 40 | 32 | 32 | 24 | 24 | 20 | 18 | |

| UNF | 80 | 72 | 64 | 56 | 48 | 44 | 40 | 36 | 32 | 28 | 28 | 24 | ||

| UNEF | - | - | - | - | - | - | - | - | - | 32 | 32 | 32 | ||

| ds | Uchafswm=Enwol | 0.06 | 0.073 | 0.086 | 0.099 | 0.112 | 0.125 | 0.138 | 0.164 | 0.19 | 0.216 | 0.25 | 0.3125 | |

| Min | 0.0568 | 0.0695 | 0.0822 | 0.0949 | 0.1075 | 0.1202 | 0.1329 | 0.1585 | 0.184 | 0.2095 | 0.2435 | 0.3053 | ||

| dk ① | Uchafswm | 0.096 | 0.118 | 0.14 | 0.161 | 0.183 | 0.205 | 0.226 | 0.27 | 0.312 | 0.324 | 0.375 | 0.469 | |

| Min | 0.091 | 0.112 | 0.134 | 0.154 | 0.176 | 0.198 | 0.216 | 0.257 | 0.298 | 0.314 | 0.354 | 0.446 | ||

| k | Uchafswm | 0.06 | 0.073 | 0.086 | 0.099 | 0.112 | 0.125 | 0.138 | 0.164 | 0.19 | 0.216 | 0.25 | 0.312 | |

| Min | 0.057 | 0.07 | 0.083 | 0.095 | 0.108 | 0.121 | 0.134 | 0.159 | 0.185 | 0.21 | 0.244 | 0.306 | ||

| s | Enwol | 0.05 | 0.062 | 0.078 | 0.078 | 0.094 | 0.094 | 0.109 | 0.141 | 0.156 | 0.156 | 0.188 | 0.25 | |

| t | Min | 0.025 | 0.031 | 0.038 | 0.044 | 0.051 | 0.057 | 0.064 | 0.077 | 0.09 | 0.103 | 0.12 | 0.151 | |

| b | Min | 0.5 | 0.62 | 0.62 | 0.62 | 0.75 | 0.75 | 0.75 | 0.88 | 0.88 | 0.88 | 1 | 1.12 | |

| c | Siamffr | Uchafswm | 0.004 | 0.005 | 0.008 | 0.008 | 0.009 | 0.012 | 0.013 | 0.014 | 0.018 | 0.022 | 0.025 | 0.033 |

| r | Siamffr | Uchafswm | 0.007 | 0.007 | 0.007 | 0.007 | 0.008 | 0.008 | 0.008 | 0.008 | 0.008 | 0.01 | 0.01 | 0.01 |

| w | Min | 0.02 | 0.025 | 0.029 | 0.034 | 0.038 | 0.043 | 0.047 | 0.056 | 0.065 | 0.082 | 0.095 | 0.119 | |

| Maint | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 3/4 | 7/8 | 1 | 1-1/8 | 1-1/4 | 1-3/8 | 1-1/2 | ||

| d | Diamedr yr Edau | 0.375 | 0.4375 | 0.5 | 0.5625 | 0.625 | 0.75 | 0.875 | 1 | 1.125 | 1.25 | 1.375 | 1.5 | |

| PP | UNC | 16 | 14 | 13 | 12 | 11 | 10 | 9 | 8 | 7 | 7 | 6 | 6 | |

| UNF | 24 | 20 | 20 | 18 | 18 | 16 | 14 | 12 | 12 | 12 | 12 | 12 | ||

| UNEF | 32 | 28 | 28 | 24 | 24 | 20 | 20 | 20 | 18 | 18 | 18 | 18 | ||

| ds | Uchafswm=Enwol | 0.375 | 0.4375 | 0.5 | 0.5625 | 0.625 | 0.75 | 0.875 | 1 | 1.125 | 1.25 | 1.375 | 1.5 | |

| Min | 0.3678 | 0.4294 | 0.4919 | 0.5538 | 0.6163 | 0.7406 | 0.8647 | 0.9886 | 1.1086 | 1.2336 | 1.3568 | 1.4818 | ||

| dk ① | Uchafswm | 0.562 | 0.656 | 0.75 | 0.843 | 0.938 | 1.125 | 1.312 | 1.5 | 1.688 | 1.875 | 2.062 | 2.25 | |

| Min | 0.54 | 0.631 | 0.725 | 0.827 | 0.914 | 1.094 | 1.291 | 1.476 | 1.665 | 1.852 | 2.038 | 2.224 | ||

| k | Uchafswm | 0.375 | 0.438 | 0.5 | 0.562 | 0.625 | 0.75 | 0.875 | 1 | 1.125 | 1.25 | 1.375 | 1.5 | |

| Min | 0.368 | 0.43 | 0.492 | 0.554 | 0.616 | 0.74 | 0.864 | 0.988 | 1.111 | 1.236 | 1.36 | 1.485 | ||

| s | Enwol | 0.312 | 0.375 | 0.375 | 0.437 | 0.5 | 0.625 | 0.75 | 0.75 | 0.875 | 0.875 | 1 | 1 | |

| t | Min | 0.182 | 0.213 | 0.245 | 0.276 | 0.307 | 0.37 | 0.432 | 0.495 | 0.557 | 0.62 | 0.682 | 0.745 | |

| b | Min | 1.25 | 1.38 | 1.5 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.81 | 3.12 | 3.44 | 3.75 | |

| c | Siamffr | Uchafswm | 0.04 | 0.047 | 0.055 | 0.062 | 0.07 | 0.085 | 0.1 | 0.114 | 0.129 | 0.144 | 0.16 | 0.176 |

| r | Siamffr | Uchafswm | 0.01 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| w | Min | 0.143 | 0.166 | 0.19 | 0.214 | 0.238 | 0.285 | 0.333 | 0.38 | 0.428 | 0.475 | 0.523 | 0.57 | |

| Maint | 1-3/4 | 2 | 2-1/4 | 2-1/2 | 2-3/4 | 3 | 3-1/4 | 3-1/2 | 3-3/4 | 4 | ||

| d | Diamedr yr Edau | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | |

| PP | UNC | 5 | 4.5 | 4.5 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |

| UNF | - | - | - | - | - | - | - | - | - | - | ||

| UNEF | - | - | - | - | - | - | - | - | - | - | ||

| ds | Uchafswm=Enwol | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | |

| Min | 1.7295 | 1.978 | 2.228 | 2.4762 | 2.7262 | 2.9762 | 3.2262 | 3.4762 | 3.7262 | 3.9762 | ||

| dk ① | Uchafswm | 2.625 | 3 | 3.375 | 3.75 | 4.125 | 4.5 | 4.875 | 5.25 | 5.625 | 6 | |

| Min | 2.597 | 2.97 | 3.344 | 3.717 | 4.09 | 4.464 | 4.837 | 5.211 | 5.584 | 5.958 | ||

| k | Uchafswm | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | |

| Min | 1.734 | 1.983 | 2.232 | 2.481 | 2.73 | 2.979 | 3.228 | 3.478 | 3.727 | 3.976 | ||

| s | Enwol | 1.25 | 1.5 | 1.75 | 1.75 | 2 | 2.25 | 2.25 | 2.75 | 2.75 | 3 | |

| t | Min | 0.87 | 0.995 | 1.12 | 1.245 | 1.37 | 1.495 | 1.62 | 1.745 | 1.87 | 1.995 | |

| b | Min | 4.38 | 5 | 5.62 | 6.25 | 6.88 | 7.5 | 8.12 | 8.75 | 9.38 | 10 | |

| c | Siamffr | Uchafswm | 0.207 | 0.238 | 0.269 | 0.3 | 0.332 | 0.363 | 0.394 | 0.426 | 0.458 | 0.489 |

| r | Siamffr | Uchafswm | 0.02 | 0.02 | 0.036 | 0.036 | 0.036 | 0.036 | 0.036 | 0.036 | 0.036 | 0.036 |

| w | Min | 0.665 | 0.76 | 0.855 | 0.95 | 1.045 | 1.14 | 1.235 | 1.33 | 1.425 | 1.52 | |

Disgrifiad manwl

Yn ôl caledwch gwifren y sgriw, y tensiwn cario, y cryfder cynnyrch ac yn y blaen, mae dosbarthiad gradd o follt soced hecsagon, hynny yw, lefel y bollt soced hecsagon. Mae angen gwahanol raddau o follt soced hecsagon ar wahanol gynhyrchion a deunyddiau i gyfateb iddynt. Mae gan bob un o'r bolltau soced hecsagon y graddau canlynol:

Mae bolltau soced hecsagon wedi'u rhannu'n folltau cyffredin a chryfder uchel yn ôl cryfder gradd. Mae bolltau soced hecsagon cyffredin yn cyfeirio at ddosbarth 4.8, mae bolltau soced hecsagon cryfder uchel yn cyfeirio at ddosbarth 8.8 neu uwch, gan gynnwys dosbarth 10.9 a dosbarth 12.9. Yn gyffredinol, sgriwiau pen cwpan soced hecsagon du gyda chnurling, lliw naturiol ac olew yw bolltau soced hecsagon gradd 12.9.

Gradd perfformiad bolltau soced hecsagonol ar gyfer cysylltiad strwythur dur yw 3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, 12.9, ac ati. Mae mwy na 10 gradd, ac ymhlith y rhain mae bolltau gradd 8.8 ac uwch wedi'u gwneud o ddur aloi carbon isel neu ddur carbon canolig ac wedi'u trin â gwres (wedi'u diffodd, eu tymheru), a elwir yn gyffredinol yn folltau cryfder uchel, a gelwir y lleill yn gyffredinol yn folltau cyffredin. Mae label gradd perfformiad y bollt yn cynnwys dwy ran, sy'n cynrychioli'r gwerth cryfder tynnol enwol a'r gymhareb bwclo o ddeunydd y bollt yn y drefn honno.

Pacio

Amdanom ni

* Mae'r diagram canlynol yn nodi'r gwahanol incotermau masnach. Dewiswch yr un sydd orau gennych.

CYNNYRCH POETH-WERTH

Ansawdd yn Gyntaf, Diogelwch wedi'i Warantu